Environmentally Friendly System

Design methodology of eco-efficient product based on Kansei engineering

Staff

- Nozomu MISHIMA (Professor, Dr. Eng.)

Research interests

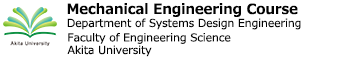

In designing products, it is necessary to consider what functions to be built in, since some functions are strongly required from users while some are not. In order to minimize environmental burden of product life cycle, embedding unnecessary features is not a good strategy. In addition, focusing not only on functions but also on outview can be efficient to design attractive and environmentally benign products. This topic focuses on both functional and visual design features and tries to show design guidelines for eco-efficient products.

Fig.1 shows the result of the case study of smartphone design. The figure indicates battery capacity, variations of color and shape are the eco-efficient design features.

| Research themes |

|---|

|

Precision engineering

Staff

- Eiki OKUYAMA (Professor, Dr. Eng.)

Research interests

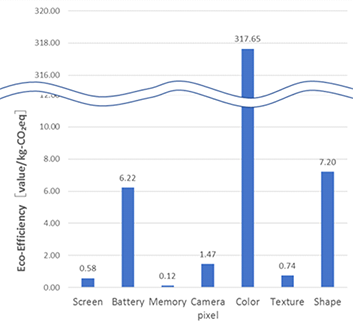

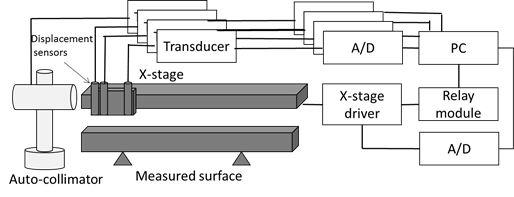

Precision measurement, especially surface profile or small displacement of mechanical components. Target repeatability is within sub-micrometer. Error separation technique, related to a straight line or a circle. Precision parasitic error motion measurement of instruments or machine tools, independent of thermal drift. Precision mechanism design, small displacement stage with high repeatability for industrial fields.

Previously, a multi-step technique for the division of length was used to decide the short scale from the large scale. An important requirement of this multi-step technique for the division of length is to keep high accuracy at several key points. We applied this technique to the integration method for surface profile measurement and proposed a combination of the large-scale integration method and the short-scale integration method.

| Research themes |

|---|

|

Heat transfer engineering

Staff

- Yoshimi KOMATSU (Associate Professor, Dr. Eng.)

Research interests

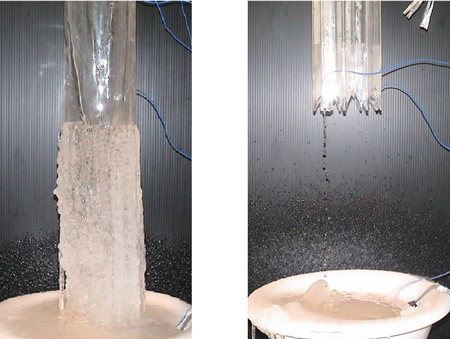

Heat and mass transfer, especially phase change phenomena in environmental and engineering fields for examination of melting of ice into seawater, thermal latent heat storage devices, and the melting of snow on roads. Freeze proofing techniques related to a drainpipe resulting from melted snow on a roof in cold districts.

Freezing begins because of droplets remaining by surface tension effects in each point at the lower end, and icicles are formed at various locations. Droplets come to remain in gaps of each icicle. Therefore, the surface area of icicles increases, thereby promoting further icicle growth. Finally, the lower end becomes completely frozen, engendering pipe blockage. We controlled the water flow by developed drainpipe. Results show that branching was reduced and flow velocity was increased. Droplets remaining on the surface of the lower end were therefore reduced, thereby suppressing freezing.

| Research themes |

|---|

|

Structural material engineering

Staffs

- Yasuyuki MIYANO (Associate Professor, Dr. Eng.)

- Yoshiaki ITO (Technical Staff)

Research interests

Material properties evaluation, especially strength of welded sections or corrosion of materials in natural environment. FSW (Friction stir welding) on middle to high carbon steel. Mechanical properties evaluation for FSW joints. Metallurgical inspection, nano-scale grain analysis for welded joints. Elucidation of the mechanism of MIC (Microbiologically Influenced Corrosion). Biofilm imaging on metal surface utilizing a newly developed observation technique.

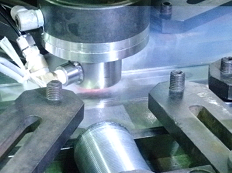

Fig.1 Overview of FSW processing

Friction stir welding on some types of carbon steel was studied. Friction stir welded joint was successfully produced under various conditions. Welded joints properties and metallurgical structure were investigated.

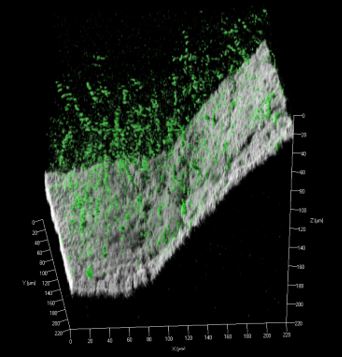

Fig.2 3D Biofilm imaging study utilizing a newly developed technique

Biofilm formation process on metal surface was observed utilizing a newly developed CSLM systems. MIC initiation process was analyzed in in-situ observation systems. We proposed innovated research style for MIC from the point view of material science.

| Research themes |

|---|

|

Regional energy system laboratory

Staff

- Takaaki FURUBAYASHI (Associate Professor, Dr. Eng.)

Research interests

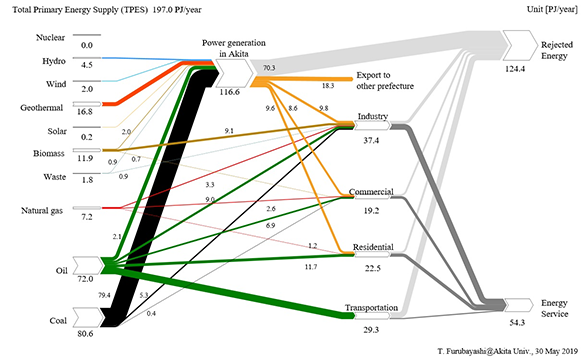

We aim to design a sustainable zero carbon regional energy system. Energy systems consist of three components; Resource, Conversion, and Demand. These components are connected by transportation processes. Resource can be divided into fossil fuels, renewables, and others such as nuclear. These resources are converted to electricity, heat, or transportation energy in Conversion process. Four demand sectors such as Residential, Commercial, Industry, and Transportation, consume these three types energy careers. It is expected that renewable energies and other new technologies are installed in target region. We analyze the effect of renewable energies and high efficiency technologies on energy efficiency, environmental impact, economic impact.

Fig. 1 shows the energy flow in Akita prefecture.The shares of petroleum in the residential and commercial sector is higher than Japan’s average because of average temperature in winter.

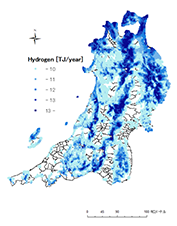

Fig. 2 shows the potential of carbon free hydrogen from wind power in Tohoku region. North area such as Aomori, Akita, and Iwate prefecture has huge potential.

| Research themes |

|---|

|

Fluid engineering

Staff

- Wataru SUGIYAMA (Lecturer, Dr. Eng.)

Research interests

Small wind turbine

Small wind turbines are often worked at unsteady wind environment. At low wind speed environment, there are very low energy levels. It is important to improve the efficiency of a wind turbine.

Rarefied gas flow

Rarefied gas flows in narrow spaces are affected by the interaction between gas molecules and walls of passages.

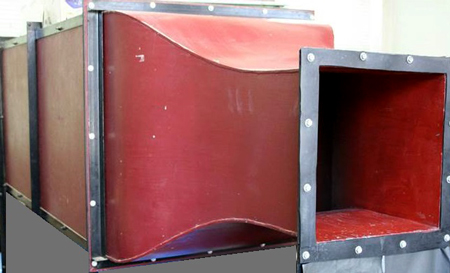

Fig.1 Wind tunnel

The wind tunnel makes uniform flow field at the outlet of the tunnel (the right side of the figure 1). Wind turbine models tested in the flow field.

Fig. 2 Vacuum chamber

The vacuum chamber is made of stainless steel. The gas in the vacuum chamber is evacuated by vacuum pumps. A passage is set in the vacuum chamber, and then rarefied gas flow in the passage is tested.

| Research themes |

|---|

|